Energy harvesting lessons

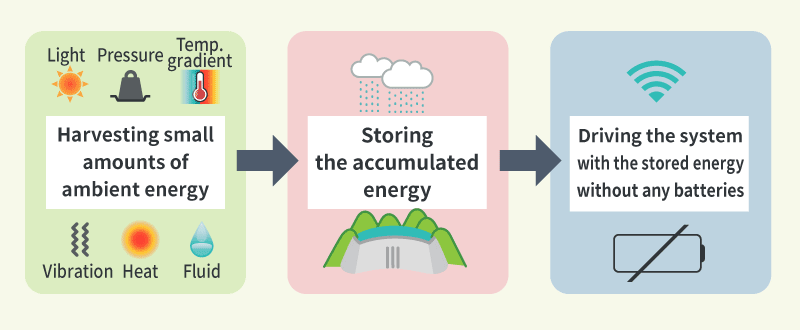

Energy harvesting roles have changed over the years as secondary battery technological advancements have improved. Methods that were used prior to this were focused on creating the lowest energy wireless devices possible because there was no good secondary source. These methods should still be considered the gold standard albeit the latest battery advancements have shifted the end goal to more of a model of product cost maintenance reduction instead of absolute energy minimization. All energy has a duration before it needs to be reinforced. The source can be asked to deliver in complex ways, bursting like a rabbit or slow and steady like a tortoise, under many conditions.

I’ve spent a lot of years working on energy harvesting. Much of the funding came from government programs. All of these platforms were wireless sensors that monitored certain aspects of machinery for preventative diagnostic purposes using some form of alternative energy. I have worked on harnessing vibration energy from helicopter blades, on electromagnetic harvesting from degaussing coils on surface ships, on thermal harvesting from pipes carrying hot fluids, the list goes on. The challenges are abounded and varied depending on the end application use case. First and foremost is the reality that most transducers are extremely inefficient (think piezo, solar cells, Peltier, etc.). Efficiencies vary, and depend on the transducer and its size, but typically for machine monitoring will fall in the 10% – 25% realm. At the time much of what I was involved with was avoidance of secondary style cells given customer concerns over chemistry and fire hazard. In most scenarios we had to rely on capacitance to store the transduced energy and do the work although we did explore testing of various chemistries and cells in an effort to move our customer to battery technology. The findings were as expected, secondary cells exhibited some form of resistance in their makeup which made pulsed applications such as wireless, especially under cold cycling impossible due to brownouts. Of course, energy harvesting had the same issues but compared to secondary cells the technology was safe and at the time the government was heavily invested in finding alternative power sources.

Another important realization with respect to energy conversion of any nature is that transducers must be tuned to an application. As one example, piezo sensors, to be effective, are mechanically built for a very narrow band of operation. If your end application has vibrational broadband frequencies don’t expect a narrow band filter to capture enough energy to run your wireless device every ten minutes. It is best to understand the end application and then target that portion of the spectrum at the piezo development itself. After development the source should be characterized through a maximum power point tracking technique. Many aspects of this development phase can cross between engineering and science and although I have been at the front door of the creation of these sensors, I do not claim to be an expert on them. I have however, been on the test end doing MPPT measurements and characterizations to define the optimal harvesters for the applications at hand.

Understanding harvesting shortcomings from traditional design and characterization certainly helps to give insight to extreme low power development of the wireless sensing systems. Within the hardware aspect it is important to keep track of not only voltage levels but also to do slope detection and monitor both incoming and outgoing rates. These rates are checked in real time as sensor code runs determining if enough energy is available for tasks or whether certain non-essential jobs need to be foregone until the next wake up period.

Creating low power applications as a designer means understanding the energy profiles of the various microcontroller jobs and their respective current requirements (i.e., wakeup, a/d, periodic timers, transmissions, re-transmissions, reception, GPIO current, etc.). Identifying these takes time and is best served using an oscilloscope and a variety of ground resistors. The end game is to integrate the area under the curve and create a look up table of energy required for each of the controller, sensor and radio tasks. The more you can discretize and quantify the individual hardware functions within the controller the more you can piece together a variety of use cases for an end product. Datasheet details become imperative as you look to create the lowest energy possible during sleep periods. The combination of sleep current and active current dictate how often a user can sense and send data for a given source capacity. In many situations, sleep current is the long pole in the tent for average power consumption. After you identify and obtain this sleep current you periodically will want to check it as you add your application code. It is very common for embedded developers to introduce working code but access a microcontroller feature in such a way as to not completely shut down the function after its use, leading to ground current creep. I have found it is still best to use microcontrollers over microprocessors and it is very realistic to expect sleep currents less than 3uA. Most low power sensor applications have simple tasks that can be done without running operating systems. A lot of embedded functionality can be done with precompiled libraries but beware a lot of times these tools do not always address the nuances of extreme current reduction. I have found myself bare metal programming many times to hit current target marks.

One of the other issues that quite frequently comes up when profiling is noise from power sources and its negative effect on measurement techniques. I have run into this many times especially at the 3uA level. Here nothing but a battery will suffice in getting the cleanest signal levels. As a matter of fact, it will create the most accurate signals even during high current events such as transmissions, sensor communication, etc.

In conclusion today’s energy harvesting is supplemented by secondary batteries and seem to allow more flexibility in the definition of what is considered low current relative to a few years back. The fundamental skills of harvesting and knowledge that I learned during those early days, along with all their complexities, allow me to make sound decisions on creating low power wireless solutions. In the end it is all about the application, maintenance cost, personnel risk, and so on that determines a products life cycle. Remember although 6uA doesn’t seem like a lot it is the difference between 5 and 10 years for a given use case when compared to 3uA. If you think it doesn’t matter imagine telling a pacemaker recipient that.